Products & Services

Polyamide Bowl Feeders

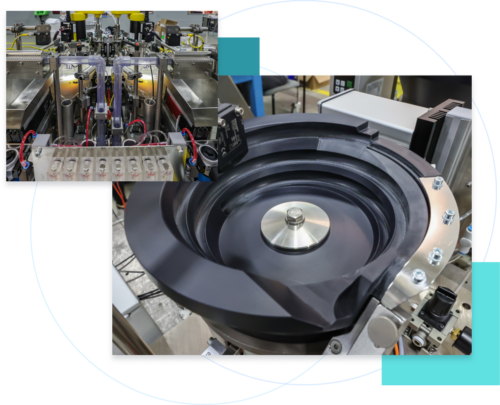

As North America's leading manufacturer, VTR's bowl feeders are an ideal choice for applications that require accurate material accountability and consistent repeatability. Our polyamide bowl feeders are designed with a calmer drive unit, which ensures they operate quietly and with minimal vibration, making them suitable for use with a variety of parts.

100% REPEATABILITY

Designed with material accountability and exact repeatability in mind.

Designed with 3D SolidWorks software and machined on a 5-Axis Trunnion CNC Mill, VTR offers machined bowl feeders equipped with a lifetime warranty. Our bowls are manufactured entirely by machines, allowing these units to be 100% repeatable. They are available in white or blue with FDA certification or black for automotive applications.

Get Started

Lifetime Guarantee

VTR's machined bowls remove variability found in hand-crafted feeder art, and come with a lifetime warranty. If the bowls fail under normal operation, VTR will replace them free of charge within days.

100% Repeatability

VTR's systems are fully designed using 3D SolidWorks software and are machined using a 5 Axis Trunnion CNC Mill. If a replacement bowl is required, our customers can simply swap the counterpart bowl by loosening a center bolt and re-installing the new bowl on dowels, without the need for a service technician.

Less Vibration

VTR's bowls use a calmer drive unit to help parts travel smoothly through the orientation features. With a higher frequency drive unit, there is no aggressive vibration transfer. Our bowls also have a smaller footprint compared to traditional hand-fabricated bowls.

PROCESS INTRICATE PARTS

Spring Detangler Available

Our machined bowls can have an integrated Spring Detangler that is specifically designed to feed springs more effectively. Spring feeder systems often struggle with tangling or jamming. VTR’s Spring Detanglers solve these issues by separating the springs and reintroducing them into the system without a large recirculation system. This helps ensure that the springs are untangled consistently, without causing jams or disruptions to the overall cycle time. The Spring Detangler is integrated into the bowl feeder itself, allowing for seamless integration into the overall system without any additional setup or maintenance. This feature can help improve the efficiency and reliability of the feeder system and ensures that springs travel into the storage track untangled and ready for processing. Our systems come with an ejection system for difficult springs.

Hoppers, Colours & Controls

Multiple Styles Available

VTR’s bowls have been designed to be flexible and can be integrated with a variety of different hopper types and accumulation devices. This allows us to tailor the feeder system to our customers’ specific needs and requirements. The different hopper types that can be used with VTR’s bowls include elevator hoppers, stepper hoppers, live bottom systems, and vibratory hoppers. Each of these hoppers has its own unique features and benefits, and selecting the appropriate hopper will depend on the specific application and the parts being fed.

In terms of accumulation devices, VTR’s bowls can be integrated with various types such as vibratory, pneumatic or conveyor based. These devices are used to collect and store parts that are fed from the bowl before they are released into the next stage of the manufacturing process. The accumulation device chosen will depend on the specific application, the parts being fed, and the desired level of automation.

VTR’s bowls are also available in different colors including black for the automotive, while white or blue, for consumer, medical or pharmaceutical. In addition, the bowls can be fitted with a control panel for a turn-key solution, which is especially useful for multilane applications and more intricate part handling. This makes it easy to quickly integrate your new system into the facility and start using it immediately.

High Accuracy & Repeatability

Escapement Options

VTR offers a variety of escapement options to take parts from storage, which are used to release parts from the feeder system in a controlled and precise manner. These options include cross shuttles, strip forward escapements, linear actuators, finger releases, placement spears, blow feed systems and rotary indexers. Each of these options has its own unique features and benefits, and selecting the appropriate one will depend on the specific application and the parts being fed.

Cross shuttles are a great option for pitch requirements. Depending on the part size, multi-pocket cross shuttles can be supplied for custom applications. With the use of a simple cylinder, the parts are released in a controlled and orientated manner.

Finger releases can be used separately or integrated with any style of escapement. The finger release system uses one or more cylinders to control the parts through the flow of the storage track, especially when parts can shingle or are flexible.

Placement spears escapement devices use a spear-like mechanism to release parts from the feeder system. The placement spear is positioned at the end of the feeder system, and employs a basic mechanical movement to discharge parts from the bowl in a controlled fashion.

Rotary indexers use a rotating cylinder or indexer to release parts from the feeder system. The rotary indexer is placed at the end of the feeder system and can use pneumatics or electrics for delivering parts to a machine. These can be designed with unique pitch requirements and for higher speed applications.

All of these escapement options have the ability to release parts with high accuracy and repeatability and can be integrated with our feeders.

Let's Start Planning.

As North America's leading manufacturer, VTR offers a lifetime warranty and 100% repeatability on our bowl feeders. With many escapement options, and a spring detangler available, we are confident we can deliver a polyamide bowl feeder that works best for your operations.

Request Quote